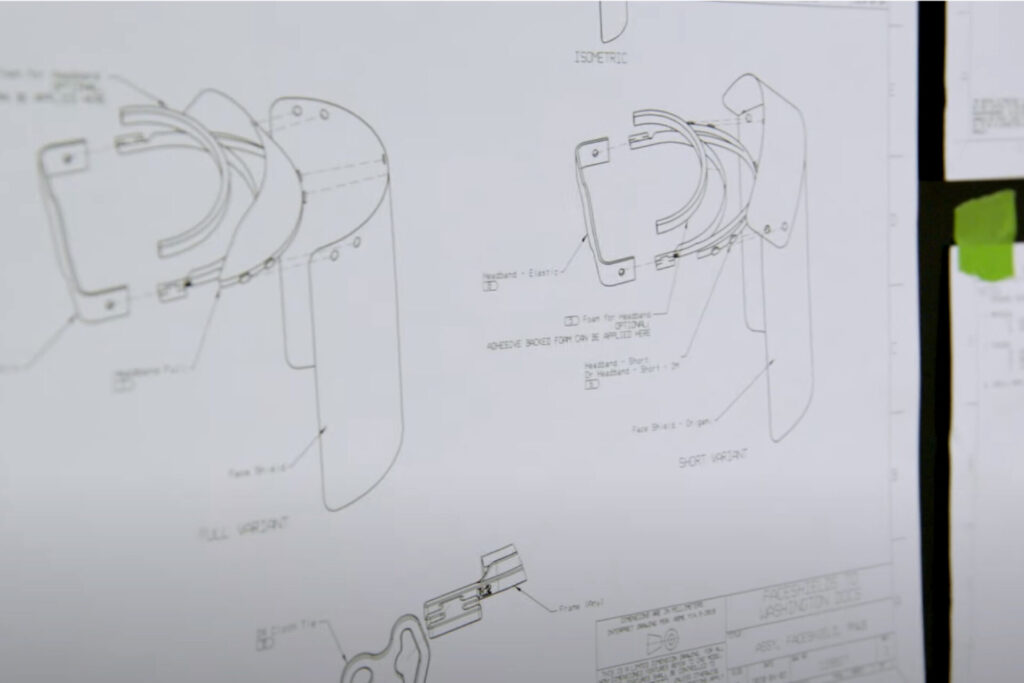

Prime Air’s mechanical design and hardware teams have created a detailed open sourced face shield design package for both 3D printing and injection molding. Engineers from Amazon’s drone team have worked hard alongside the open source group to create, invent and improve design for face shields before the final design was approved by the National Institutes of Health (NIH).

Since COVID-19 appeared the global healthcare industry has been under immense pressure, increased by the lack of PPE. A technical program manager at Amazon was inspired by a team of 3D printing enthusiasts who had been printing face shields for frontline workers and decided the Prime air team could use their expertise and innovation to help create their own safe comfortable and trustworthy face shield design.

“Making sure the shields could be produced quickly and at scale, we produced a detailed open sourced design package for both 3D printing and injection molding. This means that anyone, whether an individual or large company, can access and manufacture frames for their community’s needs. But we wanted people to also feel safe and trust what was built met the bar.”

Amazon has donated almost 10,000 face shields since the COVID-19 pandemic and is on track to deliver 20,000 more in the coming weeks. Amazon is working hard to help meet the growing demands of medical professionals and have just announced that they will now be mass-producing the face shields and selling them on Amazon.com.

“We have amazing teams creating and building every day. Watching them quickly adapt to the community’s needs during this stressful time and develop a face shield that we’ve heard from medical professionals is one of the best has been such a rewarding experience. It’s important that these critical supplies get to healthcare and government organizations and we want to help make that happen—whether that’s working with the open-source community, donating the shields, or selling these essential supplies.”